Oil tanks

Stainless steel tanks for storage and processes

Whether it is for shampoo, paint, food or pharmaceutical applications, oleochemical products serve as essential ingredients for many different products and intermediate products. In the process of refining and storing these oils, quality tanks, with the industry typical designs are essential.

Oleochemical tanks

A diverse range of tanks and other equipment is required for the processing of animal and edible oils. Gpi has a great deal of experience with producing as well as placing and installing tanks and equipment for the oleochemical industry. As a result, we are able to give the right advice on heating and cooling of products and on the correct finish level. Furthermore, we are able to guarantee a product with a long lifespan. In addition, we have good working relationships with all reputable suppliers for the right choice of agitators.

Do you have any questions?

By having engineering, production and quality control in-house, we are able to supervise quality to the greatest extent possible and guarantee you solutions which satisfy the most stringent requirements in terms of hygiene, product longevity, safety and operating convenience, for both liquids and solids. Building, testing and making your equipment operational on location is no problem at all for our SCC** certified assembly department. Naturally, we adhere to international standards and regulations.

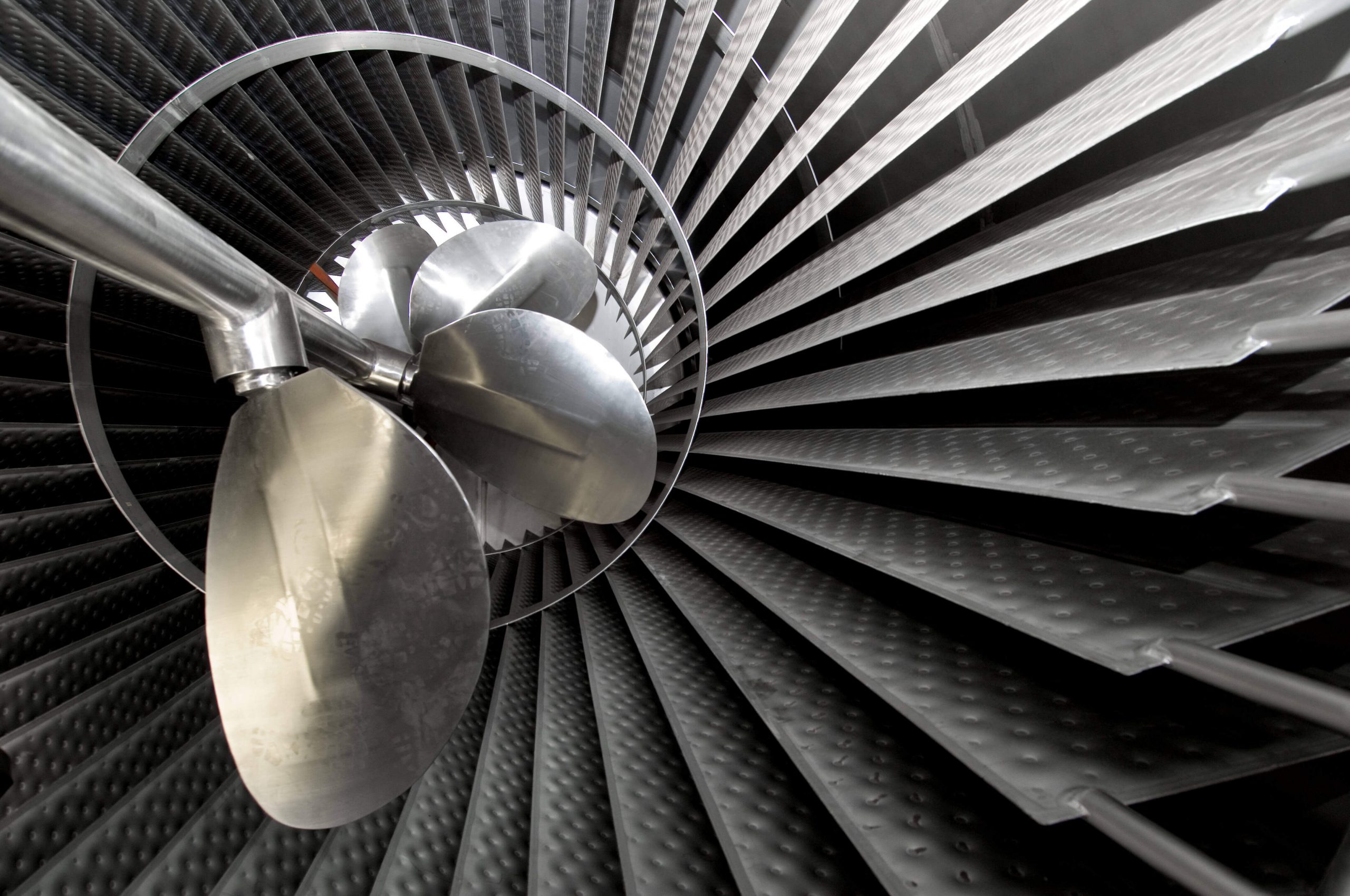

Tank agitator combinations

We can supply the agitator as well as the tank. Gpi has a good working relationship with all reputable agitator suppliers for problem-free processing and assembly.

Finishing level

As a standard, we produce our food tanks with an internal roughness of Ra 0.8, but if desired we can also produce tanks with much smoother (and therefore hygienic) inner walls.

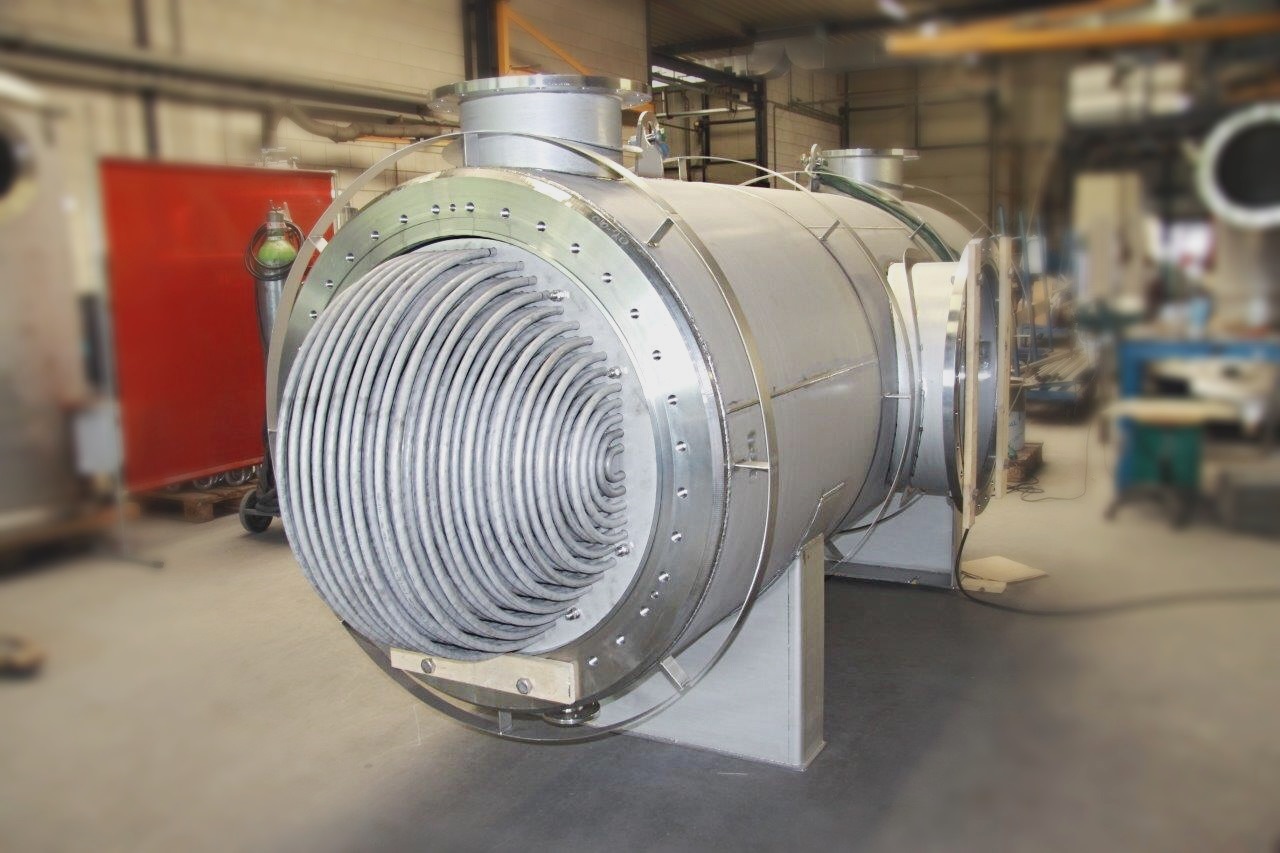

Crystallisation tanks

Crystallisation tanks are reactors in which hot liquids are gradually cooled in order to facilitate crystal growth. Gpi manufactures a range of crystallisers for use in, among other things, the processing of oil products, including a design with dimple lamella and a self-designed agitator. View a recent project using this design here.

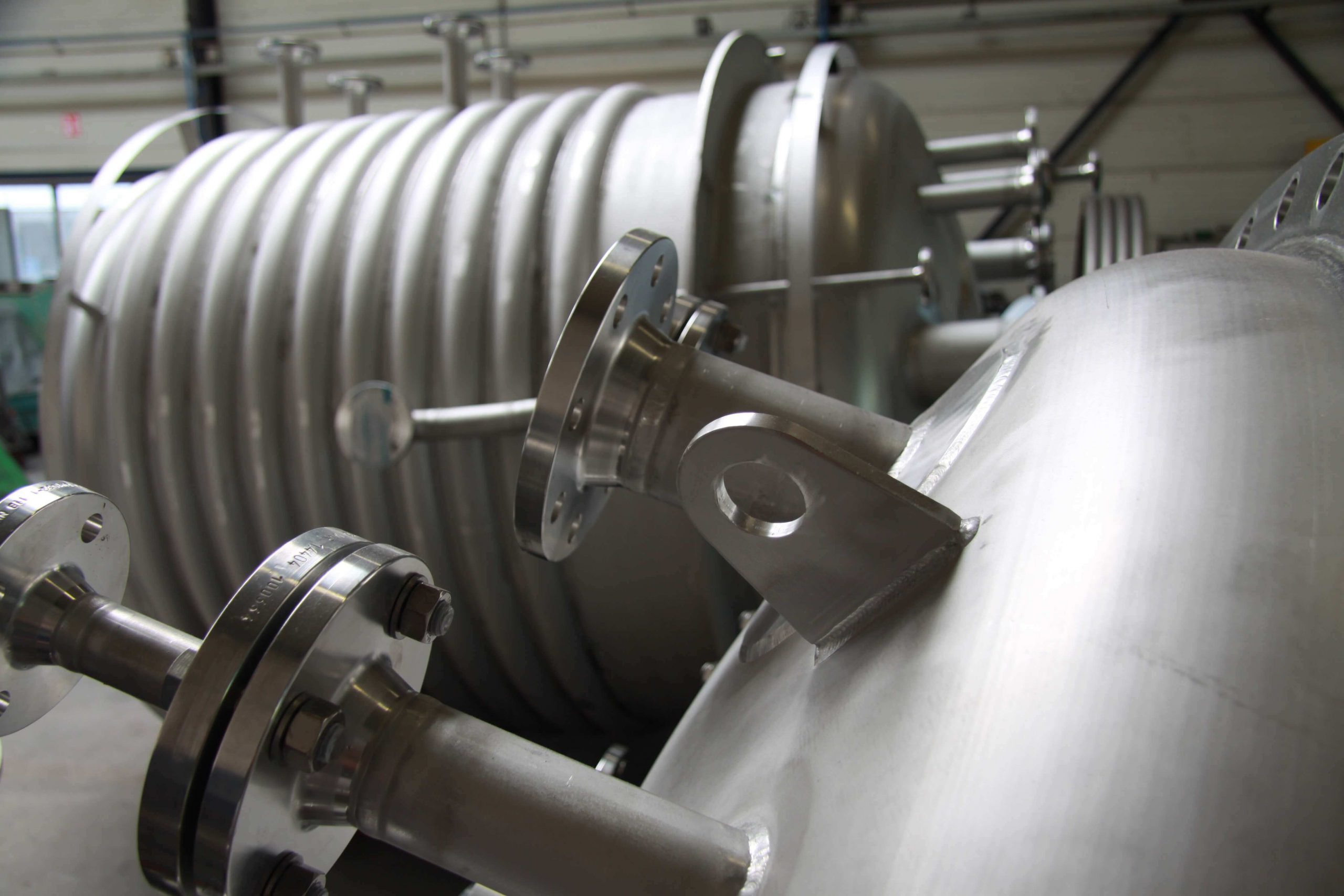

Why stainless steel oil tanks?

We produce tanks in stainless steel only. We have more than 25 years of experience in producing with stainless steel. Common types are stainless steel 304 / 304(L) and stainless steel 316 / 316(L). In many cases, the choice of type depends on the required hygiene. The right finish is also related to this: we can deliver your oil tank in any desired roughness.

Duplex tanks for oil

Duplex is an extra strong and corrosion resistant material. We see an increase in the use of duplex for tank construction. Duplex is more difficult to work with (e.g. welding), but it can be used thinner than the usual types of stainless steel. For this reason, it can sometimes be interesting to choose a duplex tank, especially for large tanks. A combination of different types is also possible. Our experts can advise you on the best choice for your project.

Certified oil tanks

We have all the knowledge and relevant tank construction certificates to deliver high-quality oil tanks. Not only do we have our own engineers and production staff, we also have our own quality control (QC) department. We are, among others, ISO 9001, ISO 3834-2, NEN-EN 1090 and KIWA BRL-K756/03 certified. This enables us to produce oil tanks in accordance with the requirements set by KIWA and with relevant construction standards. Read more about how we work and about our certificates and how we guarantee safety and quality.

Accessoires for oil tanks

A stainless steel tank with agitator

We work together with fixed partners, reputable suppliers, who can supply high-quality agitators and other fittings. We can take care of the entire handling and assembly.

Finishing of the tank

A common roughness in the food industry is Ra 0.8, but almost any finish is possible – both smoother and rougher.

Heating and cooling oil tanks

We can fully meet the specifications for your product. Both cooling and heating, or a combination, are possible. The tanks can also be insulated, resulting in a double-walled tank. We are happy to think along with you about the most efficient solution for your application.

Your oil tanks built in our factory or on location

We have two factories in the heart of the Netherlands: in Lopik and Groot-Ammers. Tanks are transported by road from Lopik and can also be shipped from our location at the water (de lek) in Groot-Ammers. If transport is possible, we build tanks in our production halls in Lopik or Groot-Ammers. If transport is not possible, we can also build tanks on site using our own efficient construction methods.

Our stainless steel tanks for oil

View the tanks and equipment that we build for this industry